If you’re working with crystals and need a reliable way to test their functionality, a test oscillator circuit offers an effective solution. This crystal tester method lets you confirm a crystal’s “active” status by comparing its output to a known good crystal. Below is a refined guide based on a classic circuit design for building and using a crystal test oscillator.

Components Needed

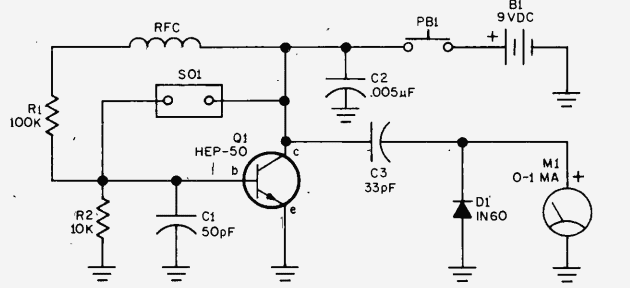

Gather these precise components for the circuit:

- 9-volt transistor radio battery

- C1: 50-pF disc capacitor

- C2: 0.005uF 100 VDC or better

- C3: 33 pF 25 VDC or better

- D1: 1N60 diode

- M1: 0-1 mA DC meter

- PB1: Normally open push button switch

- Q1: 2N2222 NPN transistor

- R1: 100K, ½-watt resistor

- R2: 10K, ½-watt resistor

- RFC: 2.5-mH RF choke

- SO1: Socket matching the crystal type

The circuit centers around a transistor (Q1), with supporting components for stability and measurement. Assemble as follows:

- Set up R1 and R2 as a voltage divider for the transistor base.

- Incorporate the RFC for oscillator stability.

- Add the push button (PB1) and meter (M1) to monitor crystal activity.

Use a socket (SO1) that matches the crystal type. For versatility, consider adding multiple sockets in parallel to test different crystal types.

Crystal tester- Testing Procedure

To evaluate a crystal’s activity:

- Insert a known good crystal and press the push button (PB1).

- Record the meter reading as your reference.

- Replace with the test crystal, press PB1 again, and compare readings.

The meter reading should closely match the reference crystal. A significant deviation may indicate a faulty crystal. Use a reference crystal of the same type for accuracy.

For improved precision, add a 1000-ohm, ½-watt, 10% resistor in series with meter (M1) if needed. Ensure all connections are secure to prevent inaccurate results.

This test oscillator is a practical tool for hobbyists and professionals, enabling quick and reliable crystal testing. Ideal for radio repairs or electronic experiments, it helps maintain component quality efficiently.